Most ceramics exhibit NTC behaviour, which is governed by an Arrhenius equation over a wide range of temperatures:

$$R=Ae^{\frac{B}{T}}$$

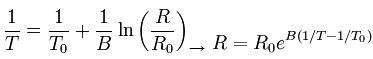

where R is resistance, A and B are constants, and T is absolute temperature (K). The constant B is related to the energies required to form and move the charge carriers responsible for electrical conduction – hence, as the value of B decreases, the material becomes insulating. Practical and commercial NTC resistors aim to combine modest resistance with a value of B that provides good sensitivity to temperature. Such is the importance of the B constant value, that it is possible to characterize NTC thermistors using the B parameter equation:

where R0 is resistance at temperature T0. Therefore, many materials that produce acceptable values of R0 include materials that have been alloyed or possess variable cation valence states and thus contain a high natural defect center concentration. The value of B strongly depends on the energy required to dissociate the charge carriers that are used for the electrical conduction from these defect centers.

NTC Thermistor

NTC Thermistors are made from certain metal oxides whose resistance decreases with increasing temperature. Because the resistance characteristic falls off with increasing temperature they are called negative temperature coefficient (NTC) sensors.

Due to the nature of the basic process the number of conducting electrons increases exponentially with temperature; the characteristic therefore exhibits a strongly rising form. This pronounced non-linearity is a disadvantage of NTC resistors and limits their useful temperature span to about 100°C. They can of course be linearised by an automation computer. However, accuracy and linearity generally do not meet the requirements over larger measurement spans. Their drift under alternating temperatures is also larger than for RTD’s. Their field of use is limited to monitoring and indicating applications where the temperatures do not exceed 200°C. In such simple applications they are actually preferable to more expensive thermocouples and RTD’s in view of their low cost and the comparatively simple electronic circuitry required. In addition they can be produced in very small designs with a fast response and low thermal mass.